Label Applicator Automatic • UK

Label Applicator Machine • UK

Elevate Efficiency with Advanced Automated Labelling Systems.

Powering Modern Production with Seamless Label Automation.

Automated Labels. Smarter. Faster.

Fully Automatic

Pay Your 50% Deposit • Reserve Your Machine

NOTE: Full Price is £4,000 GBP

No need for delays. Once you’ve paid your 50% Deposit – your machine is automatically reserved for you & then the final preparations are made to get your machine out to you. And fast!

£2,000.00

Add To Basket

Need to Send us a Message?

Contact Us

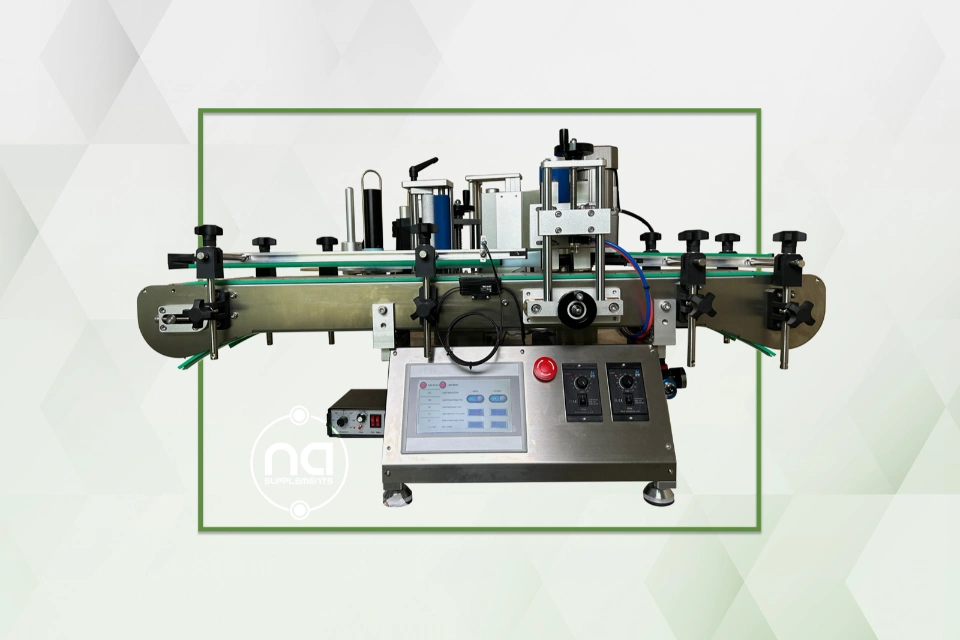

Full Automatic • Labelling Power.

Your Smooth Operating Automatic Label Applicator

Label Applicator Automatic • UK

Automated High Accuracy Labelling

Quick Specs

Full Automatic Labelling Power.

Integrated Conveyor System (1.2m).

Optional Date Coder Integration.

Built With World-Renowned Brand Components (Delta PLC, Sick Sensor).

±1mm Label Accuracy.

- High-Speed Output (25–50 Pieces/Minute).

- Wide Product Compatibility (Ø20–125mm, Height 25–350mm).

- Supports Small to Large Labels (25–200mm Length, 15–150mm Width).

- Heavy-Duty Mechanical Build (146kg).

- High-Intensity Double-Crank Mechanism.

- Pollution-Free Operation.

- Smart Inline Connectivity.

- Bottle Collecting Tray.

- Full Customization Options.

- After-Sales Guarantee & Customer Support.

Recommended for buyers seeking accuracy, consistency and reliability at an accessible price. Offering premium automatic labelling performance for growing brands.

Compatible with Multiple Cylindrical-Container Specifications

Glass bottles.

Plastic bottles.

Metal bottles.

Aluminum bottles.

Serum bottles.

Supplement bottles.

Essential oil bottles.

Pharmaceutical cylindrical bottles.

Glass jars.

Plastic jars.

Honey jars.

Food jars.

Label Applicator Automatic Machine UK

Your Next Forward Step in Professional-Grade Packaging Automation

High Speed Output • Automatic Label Applicator Machine

Fully Automatic Power • Label Applicator Machine

Built to Perform. Designed to Dominate. Spec by Spec.

£2,000.00 (50% deposit paid online) – Full price is £4,000.

UK • Sticker Applicator Automatic

-

OVERVIEW

-

PERFORMANCE

-

POWER SPECS

-

SENSOR TECH

-

MECHANICAL

Our automatic label applicator machine is a fully automatic… Conveyor-driven labelling solution designed for UK manufacturers who require speed, accuracy and professional presentation… All without the cost of higher-end, over-priced industrial systems. Built to handle a wide range of cylindrical bottles and containers… Our automatic label applicator machine delivers consistent, retail-ready labelling for food. Cosmetic. Supplement. Pharmaceutical. Chemical. And laboratory applications.

Engineered with industrial-grade components. Including a Delta™ PLC control system and a German-made Sick™ sensor… So, whether you’re based in Cornwall or Coventry, this machine offers dependable uptime. Minimal operator input. And excellent scalability for growing your production lines. And additionally, with optional date coder integration and inline connectivity… Our fully automatic label machine is ideal for your UK business. Especially, if you’re transitioning from manual or semi-automatic labelling to full automation.

Our automatic label applicator machine offers true automatic labelling performance. Providing a smooth, continuous workflow from bottle feed to finished product collection. With a labelling speed of approximately 25–50 pieces per minute… Comfortably supporting small to medium-scale production runs while maintaining consistent accuracy.

Label placement accuracy is rated at ±1mm (excluding product and label variance). Thus, ensuring a clean, professional finish across every batch. This level of precision is especially important for UK retail markets… Where presentation, compliance and brand perception directly impact sales.

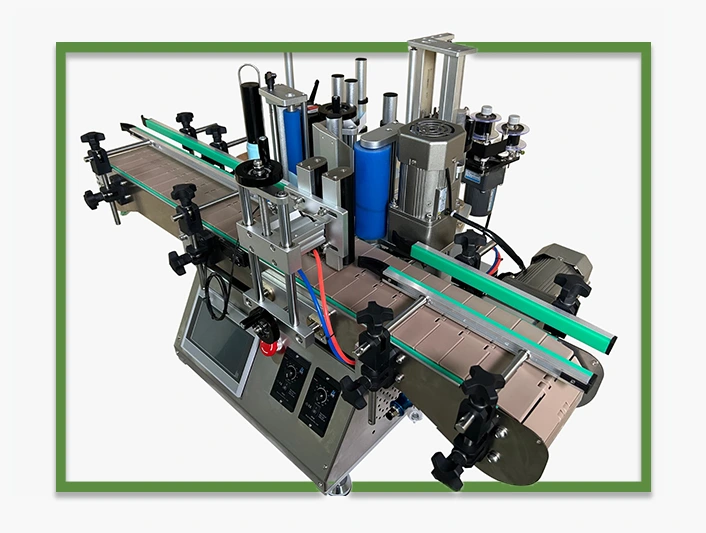

Moreover, the integrated 1.2-metre conveyor ensures controlled product movement. Thus, preventing misalignment. Skewed labels or bottlenecks commonly seen with manual handling.

Our automatic label applicator machine is designed to operate reliably on standard UK electrical infrastructure.

Power supply: 220V / 50Hz

Power consumption: 400W

This efficient power requirement makes the machine suitable for workshops. Production units. And manufacturing environments without the need for specialized electrical upgrades. Additionally, its low energy consumption also helps reduce ongoing operating costs.

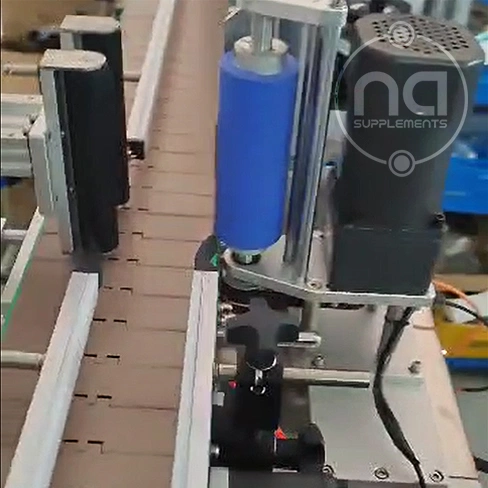

At the heart of our label applicator machine’s accuracy is its German-engineered SICK™ sensor system. a globally recognized brand trusted in high-end automation systems. This advanced sensor technology ensures precise label detection. Even when working with glossy labels. Transparent or clear labels. High-adhesion materials. And irregular print contrasts.

The Sick sensor significantly reduces the risk of missed labels. Double labelling or misreads. Thus, delivering consistent results and minimizing waste. This level of sensor reliability is rarely found in machines within this price range. Therefore, making our label applicator a standout option for UK buyers seeking long-term dependability.

Our label applicator machine features a heavy-duty mechanical structure designed for stability, longevity and consistent operation. Its high-pressure double-crank mechanism precisely controls the opening and closing motion during label application. Thus, ensuring firm, even pressure around the container.

This design is particularly effective for full-wrap labels. Thick or premium label stock. High-adhesion materials. And foil or vinyl labels.

The linear machine structure allows for straightforward installation. Easy maintenance and smooth operation. While its pollution-free design ensures clean, safe use in food-grade and cosmetic production environments.

Fast, Precise, Fully Automatic Labelling Machine • UK

25–50 bottles per minute automatic labelling.

±1mm high-precision label placement accuracy.

Delta™ PLC control system with intuitive operation.

German SICK™ sensor for reliable label detection.

Integrated 1.2m conveyor for continuous inline production.

Supports cylindrical bottles Ø20–125mm, height 25–350mm.

Handles labels from 25–200mm length and 15–150mm width.

-

DIMENSIONS

-

WEIGHT

-

PRICING

-

SUMMARY

This machine is compact enough for most production spaces while still offering full automatic capability.

Applicable product diameter: Ø20–125mm.

Applicable product height: 25–350mm.

Applicable label length: 25–200mm.

Applicable label width: 15–150mm.

Minimum label roll inner diameter: 75mm.

Maximum label roll outer diameter: 250mm.

Packaged machine dimensions: 126 × 76 × 83cm.

This wide compatibility allows our automatic label applicator machine to handle almost everything from small supplement bottles to larger jars and containers. Therefore, giving you flexibility as your UK product range evolves.

This fully automatic label applicator machine weighs approximately 146kg. Providing the stability required for high-accuracy automatic labelling.

This substantial weight prevents vibration, movement and mechanical drift during operation, which are common issues with lighter, lower-quality machines. The result is consistent label placement. Reduced downtime. And improved long-term reliability.

The full price of our Automatic Label Applicator is £4,000.00.

To make purchasing easier for UK businesses, the machine is available with a £2,000.00 online deposit (50%)… With the remaining balance payable prior to local dispatch.

This flexible pricing structure allows your growing brand to secure professional-grade automation without heavy upfront investment. Making it an accessible upgrade for you, from your manual or semi-automatic labelling systems.

Our automatic label applicator machine is a smart investment for UK manufacturers looking to improve efficiency. Accuracy. And presentation. With full automatic operation. Industrial-grade sensor technology. A robust mechanical build. And inline production capability… It bridges the gap between entry-level machines and expensive high-end systems.

Designed to scale with your business, this machine reduces your labour costs. Increases your throughput. Whilst delivering consistent, retail-ready results across every product line.

So, for brands serious about professional packaging and long-term growth… This machine offers outstanding value, reliability and performance.

UK Based • Automatic Label Applicator Machine

How to use Your Machine

Step by Step.

Fast Setup • Flexible Bottle Handling • Minimal Downtime

Load Your Bottles or Containers

- Place your cylindrical bottles or containers onto the integrated 1.2m conveyor system.

- Compatible with round bottles and jars from Ø20–125mm in diameter and heights between 25–350mm.

- This wide compatibility allows one automatic label applicator to handle multiple product lines and SKUs without additional machinery.

Adjust Bottle Guides & Label Position

- Manually adjust the bottle guides and label head to suit your container diameter and label size.

- Supports label sizes from 25–200mm in length and 15–150mm in width.

- Once set, the machine maintains consistent bottle alignment, preventing skewed or uneven labels common with inferior labelling machines.

Power On & Set Parameters

- Power on the machine using the integrated Delta PLC control system.

- Set conveyor speed and labelling parameters to match your production requirements.

- The intuitive control interface reduces setup time, operator training and the risk of labelling errors.

Automatic Application • Consistent Accuracy • Continuous Flow

Activate the Conveyor System

- Start the conveyor to feed bottles smoothly into the labelling station.

- The controlled conveyor speed ensures even spacing and stable bottle movement.

- This automated flow eliminates manual handling and improves overall production efficiency.

Automatic Label Detection & Application

- Labels are detected and applied using a German-engineered SICK sensor.

- Label placement accuracy is rated at ±1mm, ensuring clean and professional results.

- The sensor performs reliably with glossy, transparent and high-adhesion labels, reducing misreads and waste.

Optional Inline Date Coding

- If fitted, the optional date coder prints batch numbers or expiry dates during the labelling process.

- This eliminates the need for a separate coding step and reduces handling errors.

- Inline coding improves compliance, traceability and production speed.

Stable Operation • Simple Adjustments • Minimal Downtime

Stable Operation & Safety Controls

- The heavy-duty 146kg frame ensures vibration-free operation during continuous production.

- Emergency stop and safety controls provide reliable protection for operators.

- Stable mechanics help prevent misalignment and reduce unplanned stoppages.

Make Live Adjustments if Required

- Conveyor speed and labelling parameters can be adjusted easily to suit different bottle sizes.

- The machine adapts quickly when switching between products or label formats.

- This flexibility supports growing UK businesses with expanding product ranges.

Quick Clean-Down After Production

- The pollution-free mechanical design allows for fast and straightforward cleaning.

- No hydraulic oil, excessive heat or debris contamination during operation.

- Ideal for food, cosmetic and supplement environments requiring clean, hygienic workflows.

Brief Machine Comparison Benefits Summary

| Issue | Inferior Machines | Our Automatic Label Applicator Machine |

|---|---|---|

| Manual Labelling & Labour Costs | Hand labelling or semi-automatic systems require constant operator involvement, leading to fatigue, inconsistent results and rising labour costs. | Fully automatic operation with integrated conveyor. Reduces manual handling, frees staff for higher-value tasks and delivers immediate productivity gains. |

| Inconsistent Label Placement | Basic sensors and unstable bottle control cause skewed, misaligned or poorly positioned labels, leading to rejected stock. | German SICK™ sensor technology with ±1mm accuracy. Ensures clean, professional and repeatable label placement on every container. |

| Production Downtime | Lightweight frames and unreliable feeding result in frequent stoppages, rework and slow throughput. | Heavy-duty 146kg chassis with smooth conveyor-driven flow. Minimises vibration, reduces stoppages and maximises uptime. |

| Separate Coding Process | Date coding carried out as a separate step increases labour, handling errors and misaligned batch or expiry prints. | Optional inline date coder prints batch and expiry information during labelling. Faster processing, fewer errors and improved compliance. |

| Limited Bottle & Label Compatibility | Machines often support only narrow bottle sizes or specific label formats, restricting product range and future growth. | Handles cylindrical bottles Ø20–125mm and heights 25–350mm, with labels from 25–200mm. Flexibility to scale and launch new products easily. |

#1 FAQs

Your Frequently Asked

Questions

Queries

• Our Answers

What is a label applicator?

A label applicator is a machine used to apply self-adhesive labels accurately and consistently onto products or packaging. Automatic label applicators are commonly used in manufacturing to label bottles, jars and containers at speed, improving efficiency, presentation and compliance compared to manual labelling. They are widely used in food, cosmetic, supplement, pharmaceutical and chemical industries across the UK.

How to use a label applicator?

What is a sticker applicator?

A sticker applicator is another term for a label applicator, typically referring to machines that apply self-adhesive or pressure-sensitive labels. In industrial settings, sticker applicators are usually fully automatic and designed to apply labels evenly around cylindrical containers or onto flat surfaces, depending on the machine type.

What is the cost of a label applicator?

What types of products can an automatic label applicator label?

Shipping to all Corners of the UK

Offering you fast, dependable delivery across the UK. Dispatched from our London facility… Meaning no customs clearance headaches. No import delays. Nor import costs. Just smooth, local shipping you can rely on. And if you’d rather not wait, you’re more than welcome to collect your brand-new automatic label applicator in person.

#2 FAQs

Additional

Popular

Common

Frequent

Questions

Is an automatic label applicator better than manual labelling?

What bottle shapes can an automatic label applicator handle?

What is the labelling speed of an automatic label applicator?

How accurate are automatic label applicator machines?

Can an automatic label applicator print batch or expiry dates?

So, Why Buy from Us?

UK

Technicians

Support

Warranty

UK

Peace of Mind!

#1. UK-Based

#2. No Customs Hassle!

Secondly, there are no import fees. No customs charges. No international shipping surprises. You will not be hit with unexpected invoices from border agents. And you won’t have HMRC letters landing on your desk weeks after delivery. So, whether you’re based in Birmingham, Leeds or anywhere else in the UK… That risk is completely eliminated.

Your automatic label applicator machine is supplied, fully prepared for the UK market. So, simply choose your preferred delivery option, or collect it directly from our London facility in Ilford. Straightforward, predictable. And done properly.

#3. Quality and Care

What you’re getting with our label applicator isn’t just convenience… It’s engineering excellence. This is a high-value workhorse is engineered for long shifts. As well as precise, reliable performance. Our machine delivers ±1mm label accuracy and high-speed output of 25 to 50 pieces per minute. Therefore, giving you professional, retail-ready results every time. It outperforms cheaper, semi-automatic alternatives, eliminating jams, misalignments and downtime that can slow your production.

This fully automatic label applicator machine comes with a fully integrated 1.2-meter conveyor that ensures smooth, controlled container movement… Maintaining accuracy. And enabling true continuous automation inline with fillers, cappers or other production equipment. This machine handles a wide range of cylindrical containers from 20 to 125 millimeters in diameter and 25 to 350 millimeters in height. Thus, accommodating glass jars. Plastic bottles. Metal cans. Cosmetic tubes. Serum bottles. Honey jars. Food cans. And beverage bottles. It supports small to large labels with dimensions from 25 to 200 millimeters in length and 15 to 150 millimeters in width. Including full-wrap. Half-wrap. Ingredient. Cosmetic. And supplement jar labels.

Equipped with a high-end Delta™ PLC touchscreen and SICK™ sensor systems… This label applicator machine detects each container precisely. Preventing double labeling or missed labels. Even on glossy. Transparent. Or irregular surfaces. Additionally, this machine can be fitted with an optional date coder to print batch numbers. Production dates. And expiry dates… Directly on labels. Reducing labour. Whilst eliminating coding errors. Its Delta PLC™ system ensures smooth operation. Precise electronic control. And easy troubleshooting. While the heavy-duty 146-kilogram chassis and high-intensity double-crank mechanism keep the machine rock solid. Thus, preventing vibrations and ensuring consistent label application. Even on thick or high-adhesion labels.

Additionally our label applicator operates cleanly and safely. Free from odors. Hydraulic contamination. Or adhesive leaks. And it includes a bottle collecting tray for easy end-of-line handling. It can integrate with upstream equipment like filling or capping machines. Making it scalable as your production grows. Furthermore, every machine comes with a full one-year warranty covering mechanical, electrical and sensor components. And our UK-based support team provides technical assistance including setup guidance. Troubleshooting. Video support. And spare parts availability. Parts damaged through improper operation are excluded. But all genuine issues are covered.

Reliable Engineering • UK-Based Support • Premium Quality and Control

#3 FAQs

More

Answers

Replies

Response

To Your FAQs

Are automatic label applicators suitable for food and cosmetic products?

Yes. Automatic label applicators are widely used in food, cosmetic and supplement manufacturing. Machines with pollution-free operation and hygienic design are suitable for environments where cleanliness and compliance are important.

How much space does an automatic label applicator require?

Automatic label applicators are designed to fit into standard production areas. Conveyor-based machines are compact enough for workshops and small factories while still offering full automation.

Is operator training required?

Minimal training is required for most automatic label applicators. Modern machines use intuitive PLC control systems that allow operators to learn setup and operation quickly.

Can one machine handle multiple product sizes?

Yes. Automatic label applicators with adjustable guides and label heads can accommodate a wide range of bottle diameters, heights and label sizes, allowing manufacturers to run multiple SKUs on one machine.

What materials can labels be made from?

Clean, Contained, Controlled • Engineered with Stainless Steel.

A Full 12 Month Warranty

Each machine is supplied with a premium 12-month warranty from the date of delivery… Offering you peace of mind and assurance of quality. The warranty covers the replacement of any components found to be defective under normal operating conditions. With replacement parts dispatched free of charge directly to you by our dedicated support team. In the unlikely event of an issue, simply contact us and allow us to manage the process efficiently and professionally. Damage resulting from misuse, incorrect installation, or improper handling is excluded, and after the initial 12-month period. Replacement parts and delivery will be available in line with our standard service terms.

#4 FAQs

Important

Shipping

Warranty

Questions • We've Answered for You

What is the warranty period for your machines?

What if a component is damaged as a result of incorrect use or handling?

How can I request a warranty replacement?

What happens once the 12-month warranty period has ended?

Do you deliver to locations across the UK?

Are there any hidden customs or import charges for shipping?

UK

All UK Regions/Areas:

We deliver to every corner of the United Kingdom — across England, Scotland, Wales, and Northern Ireland — reaching all postcode regions, from bustling city centres to the most remote villages.

Whether you’re in AB Aberdeen. AL St Albans. B Birmingham. BA Bath. BB Blackburn. BD Bradford. BH Bournemouth. BL Bolton. BN Brighton. BR Bromley. BS Bristol. BT Belfast. CA Carlisle. CB Cambridge. CF Cardiff. CH Chester. CM Chelmsford. CO Colchester. CR Croydon. CT Canterbury. CV Coventry. CW Crewe. DA Dartford. DD Dundee. DE Derby. DG Dumfries. DH Durham. DL Darlington. DN Doncaster. DT Dorchester. DY Dudley. E East London. EC City of London. EH Edinburgh. EN Enfield. EX Exeter. FK Falkirk. FY Blackpool. G Glasgow. GL Gloucester. GU Guildford. GY Guernsey. HA Harrow. HD Huddersfield. HG Harrogate. HP Hemel Hempstead. HR Hereford. HS Outer Hebrides. HU Hull. HX Halifax. IG Ilford. IP Ipswich. IV Inverness. JE Jersey. KA Kilmarnock. KT Kingston upon Thames. KW Kirkwall. KY Kirkcaldy. L Liverpool. LA Lancaster. LD Llandrindod Wells. LE Leicester. LL Llandudno. LN Lincoln. LS Leeds. LU Luton. M Manchester. ME Medway. MK Milton Keynes. ML Motherwell. N North London. NE Newcastle upon Tyne. NG Nottingham. NN Northampton. NP Newport. NR Norwich. NW North West London. OL Oldham. OX Oxford. PA Paisley. PE Peterborough. PH Perth. PL Plymouth. PO Portsmouth. PR Preston. RG Reading. RH Redhill. RM Romford. S Sheffield. SA Swansea. SE South East London. SG Stevenage. SK Stockport. SL Slough. SM Sutton. SN Swindon. SO Southampton. SP Salisbury. SR Sunderland. SS Southend-on-Sea. ST Stoke-on-Trent. SW South West London. SY Shrewsbury. TA Taunton. TD Galashiels. TF Telford. TN Tonbridge. TQ Torquay. TR Truro. TS Teesside. TW Twickenham. UB Uxbridge. W West London. WA Warrington. WC Central London. WD Watford. WF Wakefield. WN Wigan. WR Worcester. WS Walsall. WV Wolverhampton. YO York. ZE Shetland.

From the Highlands of Scotland to the Cornish coast. From Belfast to Birmingham. Cardiff to Canterbury. Every postcode region across the UK is covered.

We deliver to rural postcodes such as IV2 Inverness. LL55 Caernarfon. PL27 Padstow. BT48 Derry/Londonderry. As well as central hubs like M1 Manchester City Centre. SW1A London Westminster. G1 Glasgow. EH1 Edinburgh Old Town. Whether your address reads BS8 Clifton Bristol. NE1 Newcastle City. CF10 Cardiff Bay. AB25 Aberdeen. Your location is already on our delivery route. Customers in remote regions like the Scottish Isles — HS1 Stornoway. KW15 Kirkwall. ZE1 Lerwick — or Northern Irish countryside — BT60 Armagh. BT34 Newry — enjoy the same fast and reliable service as those in Greater London — E1 Whitechapel. SE1 Southwark. W1 Mayfair. N1 Islington. NW3 Hampstead. Across England’s market towns — OX1 Oxford. YO1 York. NR2 Norwich. LE1 Leicester — and every village and borough in between, our delivery network is nationwide and complete.

In the South West, we reach TR11 Falmouth. EX2 Exeter. BS16 Bristol. TA1 Taunton. Across the Midlands, we cover B3 Birmingham. CV1 Coventry. NG1 Nottingham. LE2 Leicester. In the North West, we reach M15 Manchester. L1 Liverpool. PR1 Preston. BB2 Blackburn. In the North East, deliveries reach NE10 Gateshead. DH1 Durham. SR4 Sunderland. TS1 Middlesbrough. In Wales, we deliver to CF24 Cardiff. SA1 Swansea. LL11 Wrexham. NP20 Newport. Scotland enjoys full coverage from EH2 Edinburgh. G12 Glasgow. AB10 Aberdeen. DD1 Dundee. PH33 Fort William. IV51 Skye.

England – South East Region:

Surrey – GU postcode area (GU1–GU52). Covering Guildford. Farnham. Woking. Aldershot. Godalming.

Kent – ME Medway and TN Tunbridge Wells postcode areas. Covering Maidstone. Chatham. Sevenoaks. Ashford. Canterbury.

Hampshire – SO Southampton and PO Portsmouth postcode areas. Including Winchester. Fareham. Basingstoke.

Oxfordshire – OX postcode area. Including Oxford. Banbury. Witney.

Berkshire – RG postcode area. Serving Reading. Newbury. Bracknell.

East Sussex – BN and TN postcode areas. Covering Brighton. Hastings. Eastbourne. Lewes.

England – South West Region:

Cornwall – TR and PL postcode areas. Including Truro. Newquay. Padstow. Plymouth.

Devon – EX Exeter and TQ Torquay postcode areas. Covering Barnstaple. Exmouth. Brixham.

Somerset – TA and BS postcode areas. Including Taunton. Bath. Bristol.

Dorset – DT postcode area. Covering Dorchester. Weymouth. Sherborne.

Wiltshire – SN postcode area. Serving Swindon. Chippenham. Salisbury.

England – East of England Region:

Cambridgeshire – CB postcode area. Covering Cambridge. Ely. Newmarket.

Norfolk – NR postcode area. Including Norwich. Great Yarmouth. King’s Lynn.

Suffolk – IP postcode area. Covering Ipswich. Bury St Edmunds. Lowestoft.

Essex – CM and SS postcode areas. Serving Chelmsford. Southend. Colchester.

Hertfordshire – AL postcode area. Covering St Albans. Harpenden.

England – Midlands Region:

West Midlands – B Birmingham and WS Walsall postcode areas. Including Solihull. Wolverhampton.

East Midlands – DE Derby and LE Leicester postcode areas. Covering Nottingham. Loughborough. Lincoln.

Staffordshire – ST postcode area. Serving Stoke-on-Trent. Stafford.

Warwickshire – CV postcode area. Covering Coventry. Rugby. Warwick.

England – North West Region:

Greater Manchester – M postcode area. Including Manchester City Centre. Salford. Stockport.

Lancashire – BB and PR postcode areas. Covering Blackburn. Burnley. Preston.

Cheshire – CW postcode area. Serving Crewe. Nantwich. Macclesfield.

Merseyside – L postcode area. Including Liverpool. Wirral.

England – North East & Yorkshire Region:

Tyne & Wear – NE postcode area. Covering Newcastle. Gateshead. Sunderland.

Northumberland – NE and TD postcode areas. Serving Alnwick. Berwick-upon-Tweed. Morpeth.

West Yorkshire – WF and HD postcode areas. Including Wakefield. Huddersfield. Halifax.

South Yorkshire – S postcode area. Covering Sheffield. Rotherham. Barnsley.

Scotland – All Regions:

Edinburgh / Lothians – EH postcode area. Covering Edinburgh. Livingston.

Glasgow – G postcode area. Serving Glasgow City. Paisley.

Aberdeen – AB postcode area. Including Aberdeen. Peterhead. Ellon.

Dundee / Angus – DD postcode area. Covering Dundee. Arbroath.

Highlands & Islands – IV and KW postcode areas. Serving Inverness. Thurso. Kirkwall.

Wales – All Regions:

South Wales – CF Cardiff postcode area. Covering Cardiff. Bridgend. Barry.

West Wales – SA postcode area. Serving Swansea. Carmarthen. Haverfordwest.

North Wales – LL postcode area. Covering Llandudno. Wrexham. Bangor.

Northern Ireland – All Regions:

Northern Ireland wide – BT postcode area. Including Belfast. Lisburn. Derry. Armagh.

Product Short Description

Label Applicator Automatic